1

Pulp & Paper Industry

Continuous availability is crucial!

Wood becomes paper! From pulp drying to logistics. Pulp is the raw material that is indispensable in paper production. The raw material wood is with more than 80% the basis for this branch of industry. These industrial plants are in operation around the clock 24/7. Our challenge is to automate the machines and the processes for them in such a way that they are protected from breakdowns and downtime.

2

Environmental Technology

Sustainability ensures growth!

How can industry and the environment interact properly? We cannot answer this question completely, but we can help to optimize the consumption of natural resources through perfect automation processes in your plants. Gain sustainability and ensure healthy growth in the future. From the operation of sewage treatment plants or water supply systems to biogas plants, when resources are scarce, Weiss Automation GmbH is your partner.

3

Chemical industry

Optimal resource management comes first!

The chemical industry – one of the most important industries in the world.

For automation, this branch of industry brings with it a high degree of requirements due to its complexity and the linking of numerous different processes and production plants. In addition to the high safety standards, the central topics are resource and plant/production efficiency. We support many well-known companies in the continuous automation of their plants and thus provide more control.

4

pharmaceutical industry

Pharmaceutical, cosmetic and FMCG goods – efficiently produced!

We offer optimal industry solutions for the pharmaceutical industry. From modular automation to complete concepts, we can perfectly optimize and automate your processes for the production of pharmaceuticals, cosmetics and FMCG goods. Our goal is an efficient and cost-reducing production for your company.

5

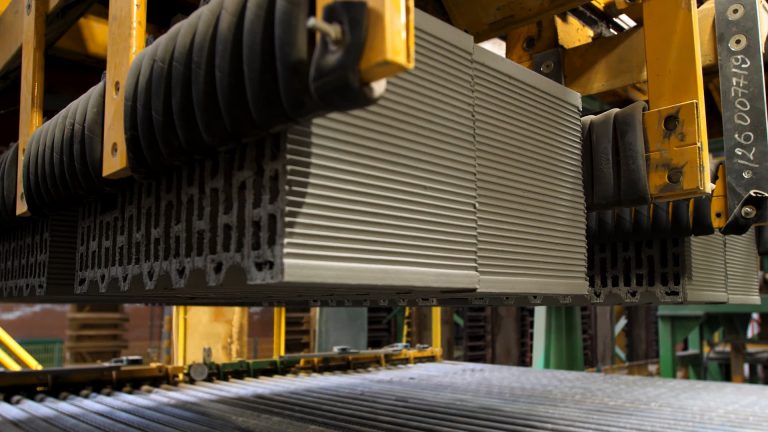

Metal industry

“Many different processes require many flexible solutions”

Highly efficient automation technology and specially adapted plant management are also indispensable in the modern metal industry. Based on a multitude of different processes and associated production steps, very flexible solutions are required for process optimization in this area. Due to our system independence, we can also integrate the optimal evaluation tools for your system and thus present the output in a highly efficient manner right from the start.

6

Ceramic industry

We make your company more efficient!

Intelligent automation for the ceramic industry means automating and controlling the numerous individual steps from firing to casting, milling, grinding, glazing, drying and polishing and making each individual step as well as the entire process measurable and optimizable for our customers. Through the system-technical connection of the individual areas, the deficiencies in the production flow can be identified and improved.

7

Food industry

“Consistently improved quality with increasing yield”.

We provide them with access to relevant real-time data, which is the guarantee for their success, especially in the food industry. Together with our partners, we ensure that they increase their production output, shorten the processing time and accelerate the packaging processes. The result is lower costs, higher quality and improved competitiveness.

8

Packaging Technology

Promote productivity – Increase your workload!

We help you to make your packaging lines more energy efficient, more flexible and more productive. Our technologies in this area are already geared to the future trends of the packaging industry and give you the possibilities to simulate and measure each process step separately. Increase your capacity utilization through perfect optimization.

9

Special machines

From “THIS IS WHAT I WANT” to “THIS IS HOW I WANT IT”…

10

Logistics

“We’ll get that extra one percent for them”.

New products need new ways – many new products need many new ways. The field of logistics is characterized by daily innovations and improvements. From storage to the point of sale, we face new challenges every day. It is our task to recognize all the small steps, to make them measurable and to derive the improvements for our customers. Logistics requires our highest degree of flexibility and planning efficiency.

11

ISO certification

The optimal way to ISO-9001/2015 certification

We accompany our customers during the ISO certification process and thus ensure that the quality of their company’s processes and products is confirmed by an accredited body.

Procedure up to certification

- Survey of existing processes and documents.

- Structuring.

- Visualization of the processes of the company.

- Development of the QM documentation:

– Management manual incl. Supplements

– process map

– work instructions - Introduction in the company.

- Internal audit by certified QM auditor.

- ISO certification from an accredited body.

temporary project management

Our expert staff will support you in the implementation from the planning stage to the final certification.

For a successful project!

With more than 15 years of experience in handling large international projects in mechanical and plant engineering and more than 10 years of experience in quality management, WEISS Automation GmbH has the necessary experience to support you in this challenge.

It's not only a job,

It's a lifestyle

Visions and dreams that we realize in our company, we carry out into the world together.

Our employees stand for innovation, modernization and efficiency.

What a career with us means

an extraordinary mix of work, leisure, family and fun, spiced with a good portion of self-realization